ADVERTISEMENT

The Ingenious Design of Milk Jugs

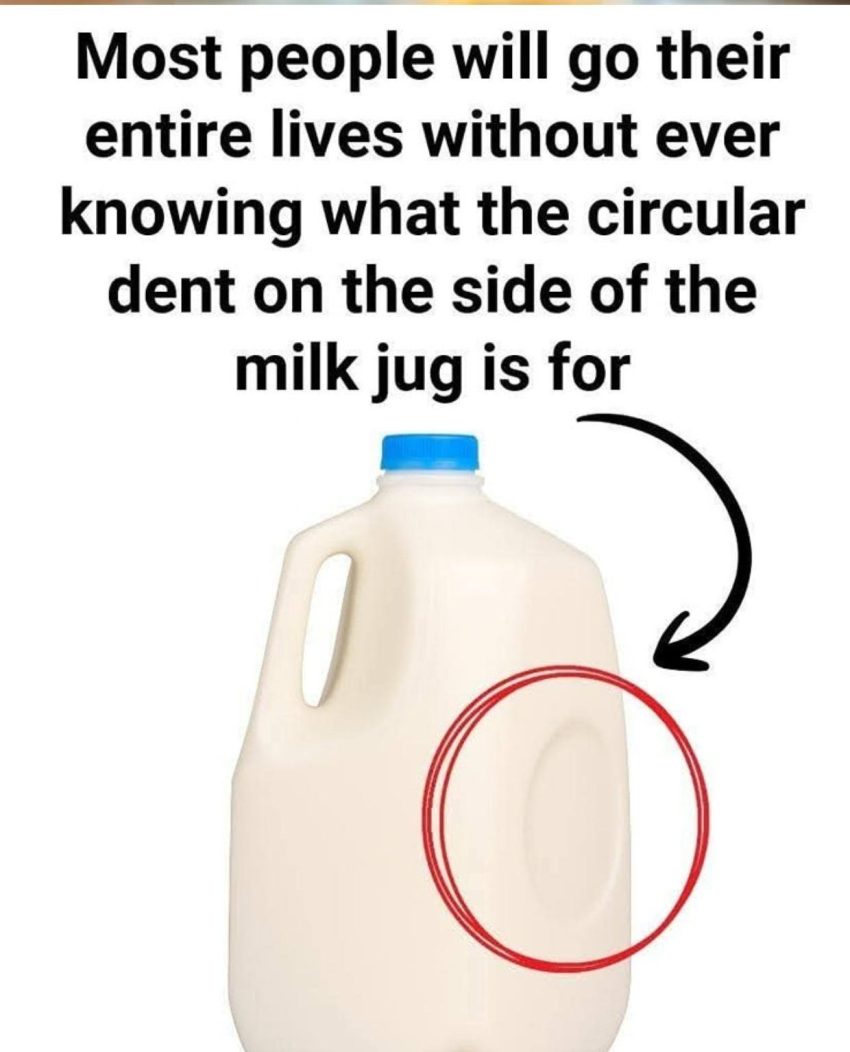

The circular dent you find on milk jugs is much more than a mere aesthetic choice. It plays a vital role in maintaining the structural integrity of the jug, particularly under varying conditions. These indentations are strategically incorporated into the design to address several practical concerns that could impact the usability and safety of milk containers.

Pressure Management

One of the primary functions of this circular dent is to manage internal pressure. Milk jugs are often subject to temperature fluctuations during storage and transportation. As the temperature changes, the milk and the air inside the jug expand and contract. Without the dent, these changes in volume could cause the jug to deform or even burst. The indentation allows the plastic to flex slightly, accommodating these pressure changes and preventing potential spillage or damage.

Impact Resistance

Another essential function of the dent is to enhance the jug’s impact resistance. During handling and transportation, milk jugs can be accidentally dropped or knocked over. The circular indent acts as a shock absorber, helping to distribute the force of an impact more evenly across the jug’s surface. This design feature minimizes the risk of cracks or leaks, ensuring that your milk stays safely contained even in less-than-ideal handling conditions.

Material Efficiency

In addition to its protective functions, the circular dent also contributes to material efficiency. By incorporating this indentation, manufacturers can use less plastic while maintaining the jug’s strength and durability. This reduction in material use not only lowers production costs but also has a positive environmental impact by decreasing the amount of plastic waste. It’s a small design tweak that delivers significant benefits both economically and ecologically.

ADVERTISEMENT